THE STORY of a NEW BUILD

Each Oceanco yacht is unique, but the process of construction – from first inspiration to final delivery and beyond – usually follows a certain path.

Here’s an outline of the chapters you can expect to find in the story of your yacht’s build.

YOUR FIRST MEETING WITH US

This is a crucial step in us understanding your vision and learning how you plan to use your yacht. It might take place on your current yacht, in your home or office, or at an event like a yacht show. You may already have a designer selected or perhaps we are your first port of call for a new yacht project. And once you have narrowed your shortlist of suitable builders to around three options, the next step is to tour their respective facilities.

SHIPYARD TOUR

Tours allow you to learn about our strengths, values, capabilities and facilities, see projects under construction, and to ensure there is a good chemistry with our top management team, which should not be underestimated. During the tour, we share potential designs, including our existing concepts, as well as relevant yacht layouts.

INITIAL PROPOSAL

We then put together an initial proposal outlining production timelines, a potential delivery date and an expected price range, alongside rough blueprint plans. This allows you to compare proposals and take the next step in committing to a single builder: signing the letter of intent, or LOI.

DEVELOPMENT PHASE

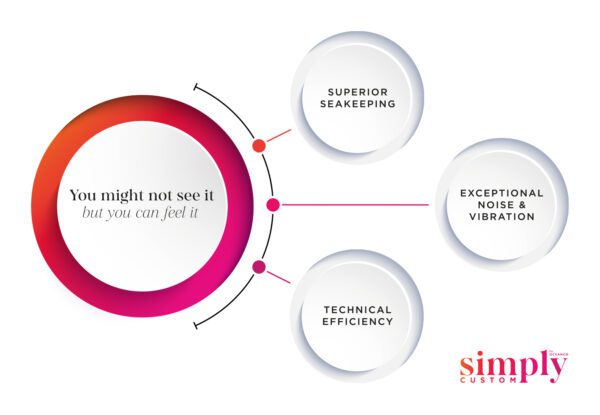

Once the LOI has been signed, this phase of the project further explores your vision. It involves multiple creative brainstorming sessions between you, our team and the designers, followed by viability assessments from the naval architects and engineers. Performance parameters are defined, and we carry out pre-engineering work to ensure the main construction and routing is on track. We request quotes from subcontractors and suppliers as well as designers, to reach a definitive price for the final contract, known as the yacht building agreement, or YBA. To give an idea of our investment during this phase, there can be upwards of 25 Oceanco professionals working on a single project, eight hours a day, for over a year.

the BUILD PROCESS

PLANNING

This is one of the most important cogs in the machinery of building a yacht as it helps to protect against unexpected costs and delays. During the development phase and before the signing the YBA, the project’s director works with you and your team to ensure all the requirements are carefully set out, that budgets are realistic and that the timelines are feasible.

ENGINEERING

Most engineering of a custom yacht takes place before the YBA is signed, when it is sometimes called pre-engineering; this is because it has an impact on the project’s viability, to ensure it is technically and legally feasible before you sign off the final design. During this phase, the design elements are converted into detailed workshop drawings and other design documents that are used to build the yacht. While the design phase might take up to nine months, the engineering phase can last another 20 to 26 months; and so to optimize the project’s efficiency these often take place in parallel. Once the engineering and design have been finalised, our procurement specialists sets about purchasing and ordering everything that goes into building the yacht.

HULL & SUPERSTRUCTURE

Building a hull is like erecting an enormous 3D jigsaw. First, vast steel plates are cut into intricate shapes that are assembled into larger steel parts, which are in turn welded to create blocks (sections of the yacht) that are eventually joined to form the hull. For a 90m yacht, typically it can take 12 to 16 months to build the hull from steel cutting to completion, with upwards of 250 to 300 people working on the project during this ‘hot work’ phase. For an average 85m hull, 800 tonnes of steel may be used, while for a 130m hull this increases to 1,500 tonnes.

A little further into the construction phase, the superstructure is erected in parallel with the hull. On a yacht of this scale, typically the superstructure is made from aluminium while the hull is steel, so they are built in different locations with superstructure engineering and construction generally taking up to 12 months.

The hull and superstructure are then fused over the course of 12 to 16 weeks, and because this ‘marriage’ results in the yacht being fully enclosed, all large systems and equipment such as engines, generators and air conditioning plants need to be positioned inside the hull beforehand.

OUTFITTING

After the marriage of hull and superstructure, the complete yacht is moved from the construction facility to the outfitting facility. The first stages of outfitting comprise the installation of all machinery, pipe systems and cable trays, as well as prefabrication works for hotel systems, involving a certain amount of ‘hot works’ before the bare metal is cleaned and painted to provide a solid foundation for the next steps. On the yacht’s exterior, outfitting includes fairing and painting of the hull and superstructure, installation of the railings, glass, teak decking, exterior bulkheads and any large furniture or items like swimming pools and bars. On the interior, outfitting incorporates the installation of the insulation, fixing of the wall and bulkhead panels, the joinery in the luxury and crew areas, and the addition of the loose furniture. Once the outfitting is finished, the yacht is launched and prepared for the final stages before delivery.

COMMISSIONING

The commissioning of a yacht is the process of ensuring all systems and components are designed, installed and tested according to the operational requirements. Once it is complete, the yacht should be fully operational.

SEA TRIALS & DELIVERY

An essential part of a new build project, during the sea trials the builder’s team, designers, naval architects and other technical teams take the finished yacht into the open water to show you, your representative, captain and build engineer, as well as the surveyors, that she meets the YBA’s specification. When everyone is satisfied with the yacht’s performance, the final stage payment is made and the yacht is handed over to you at the delivery.

WARRANTY & LIFE CYCLE SUPPORT

Large custom yachts are complex ecosystems that often need time to settle in and to iron out any possible wrinkles in performance and operation. The warranty period provides your captain and team with a grace period in which to flag nonconformities that might need resolving in order that the yacht meets the standards and specification stipulated in the YBA. And of course nobody knows your yacht better than the team that built her, so Oceanco offers ongoing support to all the yachts in our fleet, including lifetime extensions, refits and maintenance. Turn the page to learn more about this service, which we call Life Cycle Support.

END result